Crop Resource Management

“Increase productivity of sugarcane lands and profitability of sugarcane farming in a sustainable manner through appropriate improved crop, land and water management practices”

-------Quick Menu-------

The Crop and Resource Management (CRM) division has been established to identify and recommend sugarcane crop management technologies that maximize productivity and profitability from land preparation to harvesting. The division mainly focuses on how the existing resources are utilized to achieve better crop growth and finally produce maximum sugar yield.

Priority Areas

Crop physiology

Focuses on the research of sugarcane physiological aspects and finally selecting better sugarcane varieties for sugarcane variety improvement program

Crop maturity testing

Identification of the pattern of sugarcane crop maturity based on planting time and giving recommendations on planting and harvesting schedule to achieve high sugar yield

Water management

Focuses on the research of sugarcane water management practices to increase productivity and profitability with minimum environmental impact

Weed management

Giving recommendations on sugarcane weed management to increase productivity and profitability if sugarcane farming

Farming systems

Focuses on the research of maximizing resources utilization of sugarcane cultivations while reducing environmental impact

Planting techniques and ratoon management

Focuses on the research of sugarcane physiological aspects and finally selecting better sugarcane varieties for sugarcane variety improvement program

Achievements

Identification of better-ratooning varieties

SL 90 6237, SL 93 945 rain-fed and irrigated and SL 92 4918 for irrigated conditions

Introduction of intercropping for sugarcane

Recommendation on intercropping with Cowpea, Black gram, Green gram, Soybean, Groundnut, Sesame, Watermelon and Cucumber

Identifying maturity patterns of sugarcane varieties

Identification of the maturity pattern of SL 1996, SL 1998, SL 2000 and SL 2003 series varieties with planting time under irrigated conditions at Uda walawe and classifying varieties based on maturity category (Early, Mid and late)

Knowledge generation on growth physiology and yield of commercial sugarcane varieties

Cane and sugar yields and juice quality of current sugarcane varieties are sensitive to the prevailing environmental variability across the sugarcane-growing regions in Sri Lanka. Relative to the generally-considered optimum temperature of 35 °C for cane growth, the range of temperature in the sugarcane-growing regions is in the sub-optimal range. Accordingly, cane yield increases in response to the temperature increase. On the other hand, relative to the generally-considered optimum temperature of 20 °C for sucrose accumulation, the same temperature range is in the supra-optimal range and therefore caused a reduction in sucrose accumulation. If the crops are well-fertilized, climatic variability has a greater influence than soil variability. Among the climatic variables, soil water balance, maximum – minimum temperature difference and solar irradiance have the strongest influence on yield and POCS of sugarcane.

Knowledge generation on the response of growth physiology and yield of commercial sugarcane varieties

Knowledge generation on the response of growth physiology and yield of commercial sugarcane varieties to the simulated future climatic conditions (elevated air temperature and CO2)

- Increasing average seasonal maximum air temperature (Tmax) up to 34 °C increases biomass accumulation of sugarcane;

- Biomass accumulation of sugarcane varieties does not respond to the increasing Tmax from 34 to 38 °C;

- Increasing average seasonal minimum air temperature (Tmin) decreases sucrose accumulation of sugarcane;

- Increasing Tmax above 34 °C decreases sucrose accumulation of sugarcane;

- Biomass and sucrose accumulations of sugarcane varieties do not respond to the elevation of air [CO2];

- There is significant inter-varietal variation in the response of all growth, physiology and yield parameters of sugarcane to climatic variables.

Recommendations on Gliricidia mulching and trash mulching

Mulching the plant crop significantly increased cane yield in plant crop compared to un-mulching. It was revealed that the mulching in plant crop enhanced the productivity of sugarcane lands under rain-fed conditions.

Development of package of land management practices for mechanical harvesting of sugarcane

Identification of agronomically and economically appropriate land layout to facilitate machine harvesting.

Identification of good green manure species to improve sugarcane grown soils

Identification of green gram (Vigna radiata) and Sunhemp (Crotalaria juncea) as a good green manure species to improve sugarcane grown soils

During fallowing period (Vigna radiata) and Sunhemp (Crotalaria juncea) can be cultivated as green manure crops to improve soil oraganic material, Nitrogen content and soil biological properties.

Recommendations on weed management in sugarcane cultivations

Introduction of weed management package based on the sugarcane and weed growth stage and density, by combining manual, mechanical and chemical weeding methods.

Introducing weedicides for sugarcane weed management

Introducing Diron 80 WP, Krismat 75 WG, Metribuzin 70 WP for weed management in sugarcane plantations

Identification of that the preservation of cane tops as silage is a palatable feeding method for dairy cattle

Identification of agronomically and economically appropriate land layout to facilitate machine harvesting.

Analysis of nutritional quality of sugarcane top silage compared to commonly used Gini grass silage.

Analyzed the nutritional parameters of silage prepared with sugarcane tops

Introducing alternate-row furrow irrigation technique

Alternate-row furrow irrigation method saves 35 – 42% of irrigation water

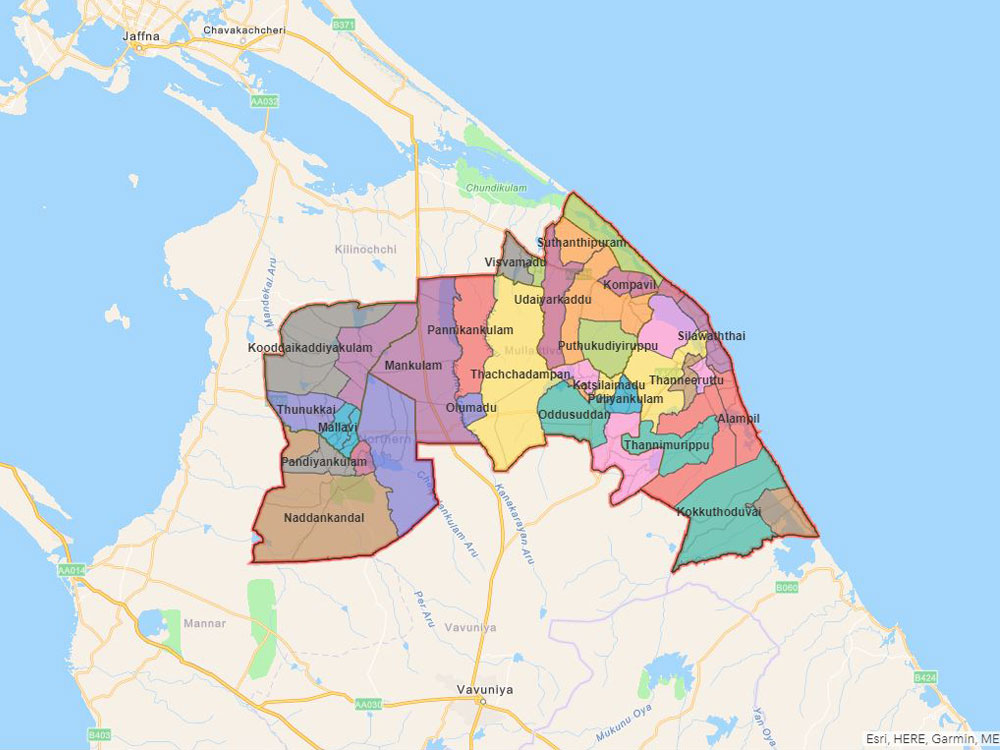

Introduction of suitable sugarcane varieties for Kilinochchi area

Evaluation and recommending SL 8306 as a suitable variety for Kilinochchi area specially for jiggery production

Establishment seedcane nursery in Kilinochchi to provide healthy seedcane for farmers

Development of a sugarcane nursery to provide healthy seed materials to sugarcane cultivators/farmers in Northern area

Expansion of sugarcane cultivation to Mulathiw, Vishvamadu area

Distribution of seed material and establishment of new plantations in non-conventional areas

Developing location-specific irrigation schedules for Hingurana sugar project

Developing a new drainage layout for safe removal of rainfall run-off water on undulating terrain.

Developing a GIS model for selecting suitable water pumps with appropriate power for lift irrigation of farmers’ fields in the rain-fed sector at Sevanagala

Introduction of newly design, low-cost and easy handling device for furrow line demarcating in furrow bed preparation.

Identification of climate change projections and their consequences on agro-climate in sugarcane growing areas of Sevanagala, Sri Lanka.

Developing a mathematical model to simulate sugarcane crop canopy height and the leaf area index in commercial plantations using GIS technology.

Assessment of potential of solar powered lift irrigation technology for Sri Lanka.

Developing an appropriate technology to estimate effective rainfall in sugarcane plantations in Sri Lanka.

Ongoing Research Activities..

Analysis of agro-meteorological conditions of major sugarcane-growing areas in Sri Lanka in 2024

To investigate the atmospheric influences on crop yields, long-term observations of meteorological parameters are necessary. Thus, recording agro-meteorological data in both spatially and temporally helps in making decisions in planning sugarcane cultivation as well as in designing and planning irrigation, drainage systems, etc.

Objectives

- To provide agro-meteorological information for sugarcane research and sugar industry development purposes.\

- To study prevailing climatic conditions in sugarcane-growing areas in the year 2024.

Investigation of water management problems in Hingurana

Due to the flat terrain of the Gal-Oya plantation, poor drainage and poor soil conditions, special attention must be paid to proper water management in sugarcane cultivation for sustainable sugarcane cultivation. Therefore, it is needed to conduct an in-depth study of all parameters that are related with water management in the area to achieve a comprehensive recommendation to rectify the issue.

Objectives

- To identify and assess the issues related to the water management situation in the Gal-Oya plantation area.

- Estimation of annual irrigation requirement and specific irrigation schedule for their 5 different administrative zones

- To prepare an irrigation zone map.

Evaluation of new sugarcane varieties of 2004 series for maturity patterns

Information about the maturity of new sugarcane varieties is required before releasing them for commercial cultivation to schedule planting for maximizing cane and sugar yield. Knowledge on the pattern of maturity of a variety is a prerequisite to decide harvesting age to get maximum yield. Therefore, the information generated from this study is useful to identify planting programs and organize harvesting operations to get the highest cane and sugar yield.

Objective

- To find out the maturity pattern of new varieties with age and planting time.

Investigation of the effect of agronomic practices on soil improvement in organic sugarcane cultivation

Since the land availability is limited, growing sugarcane continuously in the same land for a long period is a common practice adopted by many farmers. Generally, soil erosion takes place with each land preparation. Also, a substantial amount of nutrients are removed from soil while removing millable stalks with each harvest. Therefore the effect of agronomic practices on soil improvement in sugarcane crops have to be investigated under organic scenarios.

Objective

- To investigate the effect of possible agronomic practices that can be used to improve soil in organic sugarcane cultivation

Investigation of non-chemical weed management techniques in organic sugarcane

Long-term use of weedicide may contribute to environmental pollution and health issues of people. Therefore, when it comes to synthetic-chemical free cultivation, practicing integrated weed management except using the chemical methods will be the possible solution for sugarcane weed control. However the efficacy and applicability of these non-chemical weed management techniques have to be tested for the sugarcane crop also under local field situations.

Objectives

- To study the applicability and efficacy of non-chemical weed management techniques under local conditions

- To investigate the effect of non-chemical weed management techniques on sugarcane crop growth

Screening of new herbicides identified for testing weed control in sugarcane in 2024

Yield loss due to weed competition in sugarcane plantations varies from 6 % to 75%, and sometimes goes up to 100%. Adoption of integrated weed management is the best solution for sugarcane plantation. However, use of herbicide is a common practice in the sugarcane sector due to its efficacy. Therefore, finding herbicides for more economical control of weeds in sugarcane, has become necessary.

Objective

- To evaluate the effects of new weedicides for controlling weeds in the preliminary stage and in replicated experiments.

Evaluation of weedicide resistance development in major sugarcane growing areas

Continued application of the same types of chemicals on the same site as herbicides could develop a resistance of weeds to the herbicides. Due to this phenomena the weed population that is not controlled by herbicides will increase gradually. Therefore it is important to study whether weeds are developing resistance to commonly used herbicides

Objective

- To identify the weeds that are developing resistance to commonly used herbicides in sugarcane sector in Sri Lanka

Studying the maturity patterns of commercially released sugarcane varieties in Gal- Oya plantation Pvt Ltd.

Knowledge on the pattern of maturity of a variety is a prerequisite to decide harvesting age to get maximum yield. Therefore, the information generated from this study is useful to identify planting programs and organize harvesting operations to get the highest cane and sugar yield in Hingurana area

Objective

- To find out the maturity pattern of commercially cultivated sugarcane varieties in the Hingurana area against age and planting time

Evaluation of the ratoon potential of 2000 and 2003 series newly released sugarcane varieties.

Varieties differ in their ratoon potential under different management conditions and the success of ratoon cropping is influenced by the genetic traits of sugarcane varieties. Therefore this research aims to evaluate the ratoon potential of new sugarcane varieties under recommended management practices at Udawalawe, Sri Lanka.

Objective

- To evaluate the ratoon potential of new sugarcane varieties compared to standard varieties under rain-fed and irrigated conditions

Production of seedcane and expansion of sugarcane cultivation for small-scale processing industries in Kilinochchi

At present there are farmers in Kilinochchi area who are willing to cultivate sugarcane and join the sugarcane processing for jaggery and syrup production. Already a jaggery and syrup processing unit has been established at Anavillunthan with contribution of SRI and Kilinochchi district secretariat. Therefore continued supply of healthy seed cane and cultivation and processing technology for farmers are essential.

Objective

- To supply healthy seed cane for sugarcane planters in Kilinochchi district.

Publications

Peer-Reviewed / SCI Journals

- Chathuranga, G.A.A., Wijayawardhana, L.M.J.R., De Silva, A.L.C. and Witharama, W.R.G. 2023. A new pre-emergent herbicide formulation for weed control in sugarcane, Sugarcane Sri Lanka, 4: 08-17.

- Chathuranga, G.A.A., Wijayawardhana, L.M.J.R., De Silva, A.L.C., Witharama, W.R.G. and Jayathilake, Y.M.H.N. 2023. Production of silage using sugarcane tops and testing nutritional quality, Sugarcane Sri Lanka, 04: 38-43.

- De Silva, A.L.C., De Costa, W.A.J.M., and Suriyagoda, L.D.B. (2022). Effects of Elevated Temperature and CO2 on Biomass and Sucrose Accumulation of Selected Sugarcane Genotypes. Tropical Agricultural Research, 33(1): 67-79. DOI: http://doi.org/10.4038/tar.v33i1.8536.

- De Silva, A.L.C., Senarathna, H.A.K.N.N. and De Costa, W.A.J.M. (2021). Genotypic variation of the interactive effects of elevated temperature and CO2 on leaf gas exchange and early growth of sugarcane. Physiologia Plantarum. 173(4): 2276-2290. http://dx.doi.org/10.1111/ppl.13578

- Wijayawardhana, L. M. J. R., Weerasinghe, K. D. N. and Navaratne, C. M. (2021). Tipping bucket device for measuring runoff in small catchments. Hydrological Sciences Journal, 1-9.

- Wijayawardhana, L. M. J. R., Weerasinghe, K. D. N. and Navaratne, C. M. (2021). Climate Change Projections and their Consequences on Agro-Climate in Sugarcane Growing Areas of Sevanagala, Sri Lanka. Sri Lankan Journal of Agriculture and Ecosystems, 3(1).

- Wijayawardhana, L. M. J. R., Saputhanthri, S.D.T.P., Vidhana Arachchi, L.P. and Witharama, W.R.G. (2017). Management of physical properties of reddish brown earth soils at Uda Walawe (Walawa series) for sustainable sugarcane production, Sugarcane Sri Lanka, Sugarcane Research Institute, Uda Walawe, Sri Lanka. Volume -3

Read the full paper - Wijayawardhana, L. M. J. R., De Silva, A.L.C. and Witharama, W.R.G. (2017). Evaluation of alternate-row furrow irrigation technique on the growth and performance of sugarcane (Saccharum officinarum L.) grown in Reddish Brown Earth soil in Sri Lanka, Sugarcane Sri Lanka, Sugarcane Research Institute, Uda Walawe, Sri Lanka. Volume -3

Read the full paper - Witharama, W.R.G., Wijawardhana, L.M.J.R., and Chathuranga, G.A.A. (2015). The Effect of a Mixture of Glufosinate Ammonium 150g/l WSC (Basta) and Diuron 80 % WP in Controlling Weeds in Sugarcane, Sugarcane Sri Lanka, Sugarcane Research Institute, Uda Walawe, Sri Lanka. 2:1-14.

Read the full paper - Witharama, W.R.G., De Silva, A.L.C. and Wijayawardhana, L.M.J.R. (2015). Krismat 75 WG, A novel herbicide for early and late post immergence weed control in sugarcane, Sugarcane Sri Lanka, Sugarcane Research Institute, Uda Walawe, Sri Lanka. Vol 2. pp 26-35.

Read the full paper - Wijayawardhana, L.M.J.R., De Silva, A.L.C. and Witharama, W.R.G. and Nimal, W.G. (2015). Analysis of consecutive-day maximum rainfall at Uda Walawe, Sri Lanka, Sugarcane Sri Lanka, Sugarcane Research Institute, Uda Walawe, Sri Lanka. Vol 2. pp 15-21.

Read the full paper - Wijayawardane, L.M.J.R., De Silva, A.L.C. and Witharama, W.R.G. (2014). Optimizing planting schedules of sugarcane for saving irrigation water in Sevanagala and Uda Walawe, Sri Lanka, Sugarcane Sri Lanka, Sugarcane Research Institute, Uda Walawe, Sri Lanka.Vol 1. pp 15-20.

Read the full paper - De Silva, A.L.C. and De Costa, W.A.J.M. (2012). Growth and Radiation Use Efficiency of Sugarcane under Irrigated and Rain-fed Conditions in Sri Lanka. Sugar Tech. Vol. 14(3), pp 247-254. DOI: 10.1007/s12355-012-0148-y

Read the full paper - De Silva, A.L.C., De Costa, W.A.J.M and Bandara, D.M.U.S. (2011). Growth of root system and the patterns of soil moisture utilization in sugarcane under rain –fed and irrigated conditions in Sri Lanka. Sugar Tech Vol. 13(3), 198-205. DOI:10.1007/s12355-011-0088-y.

Read the full paper - De Silva, A.L.C. and De Costa, W.A.J.M. (2009). Varietal variation in stomatal conductance, transpiration and photosynthesis of commercial sugarcane varieties under two contrasting water regimes. Tropical Agricultural Research and Extension. 12(2): 97-102. DOI: 10.4038/tare.v12i2.2798

Read the full paper - Witharama, W.R.G., Naylor, R.E.L.and Whytock, G.P., (2007). Influence of Planting date and Microsite on weed dynamics in sugarcane in Sri Lanka. Weed Science, 55:23-29.

https://doi.org/10.1614/WS-05-110.1 - Witharama, W.R.G (2007). Intercropping Potential of Groundnut, Sweet Melon and Cucumber with sugarcane. Sugar Tech, 9(2 & 3): 170-175.

- De Silva, A.L.C. and De Costa, W.A.J.M. (2004). Varietal variation in growth physiology and yield of sugarcane under two contrasting water regimes, Tropical Agricultural Research vol.16:1-12. www.pgia.ac.lk › files › Annual_congress › journel › VarietalVariationPDF

Read the full paper - Witharama W.R.G. (2000 & 2001). Effect of some environmental factors on weed seedling emergence in sugarcane in Sri Lanka. Tropical Agriculturists; Journal of the Department of Agriculture-Sri Lanka, Vol. 153: 18-25.

- Rodrigo, V.H..L, Nugawela, A., Sivanathan, A., Witharama, W.R.G. and Jayasinghe, W. K. (2000). Rubber cum sugarcane intercropping; a suitable cropping system for farmers in the intermediate zone of Sri Lanka. Journal of the Rubber Research Institute of Sri Lanka, 83: 62-74.

Abstracts/ Extended Abstract /Conference papers

- De Silva, A.L.C., De Costa, W.A.J.M. and Suriyagoda, L.D.B. (2021). Effects of elevated temperature and CO2 on biomass and sucrose accumulation of selected sugarcane genotypes. pp. 14. In Proceeding of the 33rd annual congress of Postgraduate Institute of Agriculture, 17 November 2021. Postgraduate Institute of Agriculture University of Peradeniya. Sri Lanka.

- De Silva, A.L.C., De Costa, W.A.J.M. and Suriyagoda, L.D.B. (2020). Varietal variation in photosynthesis and transpiration efficiency of sugarcane at elevated atmospheric CO2 and temperature. Proceedings of the Australian Society of Sugar Cane Technologists, volume 42.

- De Silva, A.L.C., De Costa, W.A.J.M. and Senarathna, H.A.K.N.N. (2019). The varietal variation in photosynthesis and transpiration efficiency at initial growth stage of sugarcane at elevated atmospheric CO2 and temperature. pp. 99. In A. Chandra, M. Swapna, R. Manimekalai, P. Singh, A.K. Tiwari and G. P. Rao (ed) Proceedings of the International Conference of Sugarcon-2019, Green Technologies for Sustainable Development of Sugar and Integrated Industries. ICAR-Indian Institute of Sugarcane Research, Lucknow, Uttar Pradesh, India.

Read the full paper - M. J. R. Wijayawardhana, A. L. C. De Silva, B. R. Kulasekara, W. R. G. Witharama and H. M. G. N. S. C. Bandara (2019). Relationship between Cane Yield and Landscape’s Hydro-Geomorphic Parameters in Sugarcane Plantation in Hingurana, Sri Lanka. In: Proceedings of the 7th symposium on plantation crop research “Towards achieving sustainable development goals in the plantation sector” Dr. V. H. L. Rodrigo, Dr B. W. Wijesuriya, Dr. D. G. Edirisinghe, Dr. N. M. C. Nayanakantha (Eds). Rubber Research Institute, Dartonfield, Agalawatta, Sri Lanka. pp 59-66.

Read the full paper - Suvimal, W.K.D.C., Wijesekara, I., Karunarathna, W.K.D.S., De Silva, A.L.C., Weerasinghe, H.A.S., Maralanda, S.M.T.A., Wijesuriya, A. and Wickramasinghe, I. (2018). Comparative biochemical analysis of granulated jaggery from peeled and unpeeled sugarcane stems. SLCARP International agricultural Research Symposium 2018, Taj Samudra hotel Colombo, Sri Lanka.

- De Silva, A.L.C., L. M. J. R. Wijayawardhana and W.R.G.Witharama. (2017). Present Status of Research and Development on Climate Change Mitigation and Future Needs in the Sugarcane Sector in Sri Lanka, In: Proceedings of the Workshop on “Present Status of Research Activities on Climate Change Adaptations”., B. Marambe (eds), Sri Lanka Council for Agricultural Research Policy, Colombo. pp 101-112.

Read the full paper - Wijawardhana, L.M.J.R., De Silva, A.L.C. and Chathuranga, G.A.A. (2017). A new device for demarcating furrow lines for sugarcane cultivation on undulating terrain Presented at proceeding of 73rd Annual session, Sri Lanka Association for the Advancement of Science, Colombo 07.

Read the full paper - De Silva, A.L.C. and De Costa, W.A.J.M. (2016). Ratoonability of some commercial sugarcane varieties under rain-fed and irrigated conditions in Uda Walawe Sri Lanka. 3 pp. In N. S. B. M. Atapattu (ed) Proceedings of the International Symposium on Agriculture and Environment 2016. Faculty of Agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka.

Read the full paper - Wijayawardane, L.M.J.R., De Silva, A.L.C. and Witharama, W.R.G. (2016). Evaluation of alternate-row furrow irrigation technique on the growth and performance of sugarcane (Saccharum officinarum L.) grown in Reddish Brown Earth soil in Sri Lanka. pp. 137-147. In V. R. M. Vidhanaarachichi, H. M. I. K. Herath, M. K. Meegahakumbura, A. D. N. T. kumara and M. K. F. Nadheesha (ed) Proceedings of the 6th symposium on plantation crop research – “Plantation Agriculture towards National Prosperity” Coconut Research Institute, Lunuwila, Sri lanka.

Read the full paper - De Silva, A.L.C., Wijesuriya, A. and Wijayawardane, L.M.J.R. (2014). Genetic potential of sugarcane (Saccharum spp. Hybrid) and its wild relatives (Saccharum spontaneum and Erianthus arundinaceous) for improvement of shoot and root growth and stomatal resistance. pp. 53-61. In A. P. Keerthipala (ed) Proceedings of the Fifth Symposium on Plantation Crop Research – “Towards a Green Plantation Economy” Sugarcane Research Institute, Uda Walawe, 70190, Sri Lanka.

Read the full paper - Wijawardhana, L.M.J.R., De Silva, A.L.C. and Witharama, W.R.G. (2014). Optimizing Planting Schedules of Sugarcane for Saving Irrigation Water in Sevanagala and Uda Walawe, Sri Lanka. pp. 105-110 In A. P. Keerthipala (ed) Proceedings of the Fifth Symposium on Plantation Crop Research – “Towards a Green Plantation Economy”. Sugarcane Research Institute, Uda Walawe, 70190, Sri Lanka.

Read the full paper - De Silva, A.L.C. and De Costa, W.A.J.M. (2014). Sucrose accumulation and maturity patterns of sugarcane under rain-fed and irrigated conditions in Sri Lanka. pp. 115-118. In N. S. B. M. Atapattu (ed) Proceedings of the International Symposium on Agriculture and Environment 2014 – “Ensuring Sustainable Development through Biodiversity and Ecosystem Services” Faculty of Agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka.

Read the full paper - Wijawardhana, L.M.J.R. De Silva, A.L.C. and Witharama, W.R.G (2013) Assessment of Water Requirement of Sugarcane, Banana and Paddy in Sevanagala. Presented at proceeding of 69th Annual session, Sri Lanka Association for the Advancement of Science, Colombo 07.

Read the full paper - De Silva, A. L. C., Ariyawansha, B. D. S. K., Wijayawardana, L. M. J. R. and Witharama, W. R. G. (2012). Effects of mulching on growth and yield in plant crop of sugarcane under rain-fed conditions in Sevanagala, Sri Lanka. Proceedings of the Fourth Symposium on Plantation Crop Research 21st-22nd September 2012, Colombo, Sri Lanka.

Read the full paper - De Silva, A.L.C. (2012). Varietal variation in stomatal conductance of sugarcane under rain-fed conditions in Sri Lanka. Proceedings of the Symposium on Minor Export Crops, 16-17 August 2012, Peradeniya, Sri Lanka. pp 123-128.

Read the full paper - De Silva, A.L.C. (2012). Diurnal variation in stomatal conductance of sugarcane varieties under rain-fed conditions in Sri Lanka. Proceedings of the International Symposium on Agriculture and Environment 2012. 29th November 2012, Faculty of Agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka. pp 186. (Abstract)

Read the full paper - De Silva, A.L.C. (2012). Water use efficiency in commercial sugarcane varieties under irrigated and rain-fed conditions in Sri Lanka. Proceedings of Research Symposium on meeting global challenges through knowledge and wisdom, 22-23 November 2012, Uva Wellassa University of Sri Lanka. Badulla, Sri Lanka. Vol. II, pp 531-534.

Read the full paper - De Silva, A.L.C. and Witharama, W.R.G. (2011). Advantages of cane tops as a planting material in spaced transplanting technique of sugarcane, In: Proceedings of the International Symposium on Agriculture and Environment 2011. Faculty of Agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka. p 20.

Read the full paper - Wijayawardhana, L.M.J.R., Abeyrathna, K.H.D., Witharama, W.R.G., and Keerthipala, A.P. (2011). Run-off harvesters and agro-wells for supplementary irrigation of rain-fed sugarcane at Sevanagala in Sri Lanka: A preliminary investigation. 16th International Forestry and Environmental Symposium, University of Sri Jayawardhanapura, Sri Lanka.

- Kumarasinghe, N.C. and Wijayawardhana, L.M.J.R. (2011). Effect of climatic condition on sugarcane cultivation in Sri Lanka. International Conference on the Impact of Climate Change on Agriculture, Faculty of Agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka.

Read the full paper - De Silva, A.L.C., De Costa, W.A.J.M. and Bandara, D.M.U.S. (2010). Growth of root system and the patterns of soil moisture extraction in sugarcane under rain-fed and irrigated conditions. Proceedings of the International symposium 2010. 16th November 2010, Faculty of agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka. p5.

- Witharama, W.R.G. and De Silva, A.L.C. (2010). Effects of stubble shaving, fertilization and gap filling on the performance of sugarcane (Saccharum officinarum L.) ratoon crops in Sri Lanka. In: Proceedings of the Third Symposium on Plantation Crop Research– Stakeholder empowerment through Techno-logical Advances (Eds.R.S.Dharmakeerthi and A.M.W.K.Senevirathna) Rubber Research Institute of Sri Lanka, Dartonfield , Agalawatta. pp 189-199.

Read the full paper - De Silva, A.L.C., De Costa, W.A.J.M. and Bandara, D.M.U.S. (2010). Growth of root system and the patterns of soil moisture extraction in sugarcane under rain-fed and irrigated conditions. Proceedings of the Inter national symposium 2010. 16th November 2010, Faculty of agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka. p5.

- De Silva, A.L.C. and Witharama, W.R.G. (2010). Optimum inter-settling spacing and potential of using cane tops in spaced transplanting technique of sugarcane in Sri Lanka, In: Proceedings of the Third Symposium on Plantation Crop Research – Stakeholder empowerment through Techno-logical Advances. Colombo, Sri Lanka. pp 108-120.

Read the full paper - De Silva, A.L.C. and De Costa, W.A.J.M. (2009). Varietal variation in stomatal conductance, transpiration and photosynthesis of commercial sugarcane varieties under two contrasting water regimes. Proceedings of the Second National symposium 2009. 10th September 2009, Faculty of agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka. p14 .

Read the full paper - De Silva, A.L.C. (2008). Varietal variation in canopy development and radiation interception of sugarcane under two contrasting water regimes, Proceedings of the National symposium 2008. 23nd -24th October 2008, Faculty of Agriculture, University of Ruhuna, Mapalana, Kamburupitiya, Sri Lanka. p17.

- De Silva, A.L.C. (2008). Evaluation of Agronomic traits, their correlation to yield and ratoononing ability of near commercial sugarcane varieties under supplementary irrigated and rain-fed conditions, Proceedings of the Second Symposium on Plantation Crops Research 16th-17th October 2008, Bandaranayake Memorial International conference Hall, Colombo 07, Sri Lanka.

Read the full paper - Witharama, W.R.G. (2007). Effect of sprayer nozzles on efficacy and economy of spraying herbicide in sugarcane. Proceedings of the 21st Asia Pacific Weed Science Society Conference, Colombo, Sri Lanka: 513-517.

- De Silva, A.L.C. and De Costa, W.A.J.M. (2004). Varietal variation in growth physiology and yield of sugarcane in Sri Lanka under two contrasting water regimes, International Crop Science Congress, Brisbrane. Australia.

Read the full paper - Witharama W.R.G. (2002). Effect of sprayer nozzles on efficacy and economy of spraying herbicide in sugarcane. Proceedings of the 58th Annual Sessions 2nd to 07th December, Part 1 – Abstracts of presentations: 27.

- Witharama W.R.G. (2001). Studies on crop weed competition in sugarcane, variety Co. 775. Proceedings of the 57th Annual Sessions 26 November to 01 December, Part 1 – Abstracts of presentations: 33.

- Witharama, W.R.G. (2000). Fact Sheet; A quick guidance to a weed of national significance in Sri Lanka – Lantana camara L. A publication of the ministry of Forestry and Environment.

- Witharama W.R.G. (2000). Association of the seed bank and emerged weeds in sugarcane in Sri Lanka. Proceedings of the 56th Annual Sessions 27th November to 01st December, Part 1 – Abstracts of presentations: 61.

- Maddumage, P., Ranaweera, K.K.D. and Witharama, W.R.G. (1998).Effect of depth of seed bury on germination and emergence of weed seedlings. Proceedings of the 54th Annual Sessions 14th to 19th December, Part 1 – Abstracts of presentations: 104.

- Witharama, W.R.G., Naylor, R.E.L. and Whytock, G.P. (1997). The seed bank and weed seedling emergence in sugarcane in Sri Lanka. Proceedings of the Brighton Crop Protection Conference – weeds: 663-664.

Bulletin/Puwath/Newspaper articles

Books / Book Chapters

- De Silva, A.L.C. (2011). Physiological behavior of sugarcane in sub-humid climatic conditions. LAP LAMBERT Academic publishing Gmbh & Co. KG, Germany.p142. [ISBN:978-3-8454-0336-6].

http://www.amazon.com/s/ref=nb_sb_noss?url=search-alias%3Dstripbooks&field-keywords=9783845403366&x=17&y=20

Advisory Circulars

Patents

Other publications

- De Silva, A.L.C. (2021). Varietal response of sugarcane to changing climate and soil conditions in Sri Lanka. Unpublished PhD thesis. Postgraduate Institute of Agriculture, University of Peradeniya, Sri Lanka.

- De Silva, A.L.C. (2007). Investigation of growth, yield, ratooning ability and some important physiological attributes of a selected set of commercial sugarcane varieties in Sri Lanka under irrigated and rainfed conditions. Unpublished MPhil. Thesis Postgraduate Institute of Agriculture, University of Peradeniya, Sri Lanka.

- Witharama, W.R.G. (1998). Studies on weed populations in sugarcane in Sri Lanka. PhD Thesis. University of Aberdeen. https://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.242099

Our Staff..

Dr. A.L.C. De Silva

Senior Research Officer

Ph.D. University of Peradeniya

M.Phil, University of Peradeniya

B.Sc, University of Ruhuna

Research Interest: Crop Physiology

- alc@sugarres.lk

- alc_desilva@yahoo.com

- alcdesilva@gmail.com

- ResearchGate

- ORCiD

Mr. L.M.J.R. Wijayawardhana

Research Officer

Phd.

M.Phil, University of Ruhuna

B.Sc (Agric.), University of Ruhuna

Research Interest: Water Management

- lmjrw@yahoo.com

- ResearchGate

Mr. G.A.A Chathuranga

Research Officer

M.Sc, Environmental forestry, University Of Peradeniya

B.Sc (Agricultural technology and Management.),

University Of Peradeniya

Research Interest: Conducting research on sugarcane agronomy

- amilacga@sugarres.lk

- ResearchGate

Mr. P.R.B Chandrasena

Farm Superintendent

M.Sc, University of Peradeniya

B.Sc (Agric.), Sabaragamuwa University

Job Role: Farm Superintendent

- larypel@yahoo.com

Mr. W.G. Nimal

Technical Officer

Job Role: Assisting research staff for research

Mr. I.P Manawadu

Technical Officer

Job Role: Assisting research staff for research

Mr. D.M.G.H Chathuranga

Technical Officer

Job Role: Assisting research staff for research